- Call Us : 044 - 4301 6191

- Email us : marketing@shreevenus.com

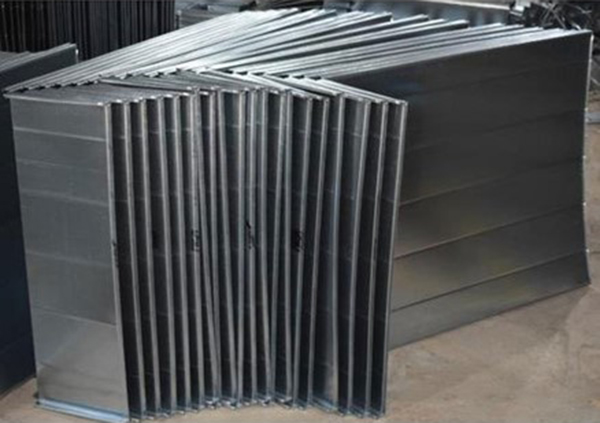

The growing need of quality air ducts and scarce availability of skilled man power and shortest time duration available for manufacture of ducts, we need to quip with sophisticated CNC machinery to produce quality duct. To overcome these factors for successful execution of project, VENUS has emerged with CNC fabricated machine-made ducts.

VENUS ducts are manufactured using the state-of-the-art world class machine manufactured and imported from U.K.

These machinery assures quality products which meets the requirement of international standards of SMACNA {USA} and DW 144 {U.K.}

ADVANTAGES OF USING FACTORY MADE PRE-FABRICATED DUCTS:

VENUS factory made ducts utilizes the state-of-the-art CAD/CAM sheet metal fabrication machinery.

VENUS has put up its facility, utilizing leading-edge, world class sheet metal fabrication and profiling technology. We provide excellent products for your money.

Superior quality profiles and sections, making use of state-of-the-art CAD/CAM to ensure perfect dimensional products and perfect fitting sections are produced.

SPEED: Efficient handling of the equipment for manufacture of ducts considerably reduces fabrication and therefore job completion time is minimum.

COST EFFECTIVE: An innovative approach of transporting pre-performed sections {instead of more blank sheets} enables easy assemblying and installation at sites all over India-economically and perfectly.

CLEAN JOB SITES: Space requirements is minimum, avoidance of scrap and reduction of noise and disturbance at site..

RAW MATERIAL IN COIL FORM : Prime grade coils of G.I., aluminum and stainless steel sourced directly from the manufactures to get quality materials. This ensures uniformity of material properties, availability of wide range of material specifications as per customer requirements and significantly low wastage.

MANUFACTURING FACILITIES

CAD/CAM MACHINERY : Precision dimensioning, speed and excellent raw material usage are provided by fully automated, computer-controlled machine through the below mentioned machinery.

AUTOFOLDER : Which selects the required sheets, gauge, levels, provides, stiffening ribs, notches, folds and shears for the manufacture of flats “L”, “U” and fully boxed sections.

PLASMA PROFILE CUTTER : Which produces the widest range of profiles for Elbows, tapers, offsets, branches and other sections etc.,

STANDARD SELECTION TABLE

Manufacturing of these profiles is carried out by a small but highly-skilled and trained technical work-force at our factory.

Apart from quality, these machines also ensure timely delivery of ducts system to meet the Project requirements, thus completion of project is faster.

CONCLUSION : The end result of this manufacturing sophistication are, duct profiles and sections which have high strength, low leakage and low vibration characteristics. They require lighter guage material than those produced by conventional means, coupled with the speed of manufacturing, this translates in to unmatched economy and reliability.

RIGID SPIRAL DUCTS

M/S.Shree Venus Energy manufactures Rigid Spiral Ducts using the State-of-the-art latest Hi-tech machines from Spiro International, Switzerland, the pioneers in manufacturing of Spiral duct machines in the world.

The duct manufactured in the machines meets highest air tighteners classification as per international standards.

Advantages of using Spiral ducts are

Fabrication and installation cost are significantly lower

The air tightness meets the highest classification

Superior strength allows for saving on metal

Pressure drop is lower

Naturally the strongest system

Inside cleaning of duct is more effective

Requires less space

Leakages through the duct system is minimized

Can be used as architectural features

Cost effective

RANGE OF PRODUCTS

| Diameter Range | From 80mm dia to 1600mm dia |

| Diameter Range | 0.4mm to 1.2mm thickness |

| Tube Length | Unlimited |

| Material | Aluminum, Brass, Copper, Zinc, Galvanized,CRCA Steel, Stainless Steel or Plastic-Coated Steel |

FITTINGS

Different fittings like Elbows, Reducers are made in a specially designed Gorelocker machine from M/s. Spiro, Switzerland, ensures the uniformity of sizes and trouble-free erection at site. Also, the air tighteners classification meets the International Standards.

PRE-INSULATED PIPES FOR HIGH PERFORMANCE INSULATION SYSTEMS

Shree Venus was established in 1993 for making PUF slabs and pipe sections and PUF pipe supports. Shree Venus also specialized in cast insitu type insulation of pipes and tanks at site. The growing need of quality insulation and for better energy conversation, Venus has emerged with pre-insulated pipes with the help of State-of-the-Art latest machines from Spiro, Switzerland for making spiral seam casing and for pouring of PUF, the machines are imported from Saip Italy.

Advantages of using Pre-insulated pipes with Polyurethane foam are:

Superior strength allows for saving on metal consumption over insulation.

No deformation of shape in case of people walking / Climbing over the pipes after insulation.

Retains the shape and no damage to insulation, in spite of regular foot traffic over the Insulation. Hence maintenance cost is less compared of conventional system.

Water ingress inside the insulations is nil due to seamless insulation of Polyurethane foam and least number of joints on metal jacketing, which prevents the corrosion of inside pipe due to water ingress in case of exposed pipes to weather and hence increases the life of Pipes and insulations.

Site installation of insulation can be reduced to minimum, to cover the elbows, valves, flanges and welding joints and other fittings. Hence, it is economical.

Dependence on labour for site is minimized. Hence, fast completion assured.

FILLED JOINTS

Field joints and fittings like elbows, reducers and Valves are carried out with high pressure Injection machines which ensures uniform quality of foam / density like pre insulated pipe.

High pressure injection ensures the pipe insulation and Spiral casing form an integral part of Seamless pipe insulation system due to uniform foam quality.

The high-pressure machine injection ensures complete filling of irregular surfaces in places like Elbows, Reducers, Valves and Flanges compared to manual pouring method.

SPECIFICATIONS

| Insulation | CFC free |

| Material | Rigid Polyurethane Foam |

| Thickness | 25mm and above |

| Density | 36-40 Kgs. /M3, Other densities can be given upon request |

| Fluid Temp Range | (-) 185°C to 110°C |

| Sizes | Pipe diameter shall be from ¾” onwards |

| Pre-insulated pipe length | 6m |

| Outer jacket | |

| Above ground | GI/AL/ Stainless Steel / Pre coated GI |

| Underground | HDPE / PVC |

| Fire Property | |

| Self-Extinguishing ASTM D 1692 (Fire Retardant foam Chemicals) | Passed |

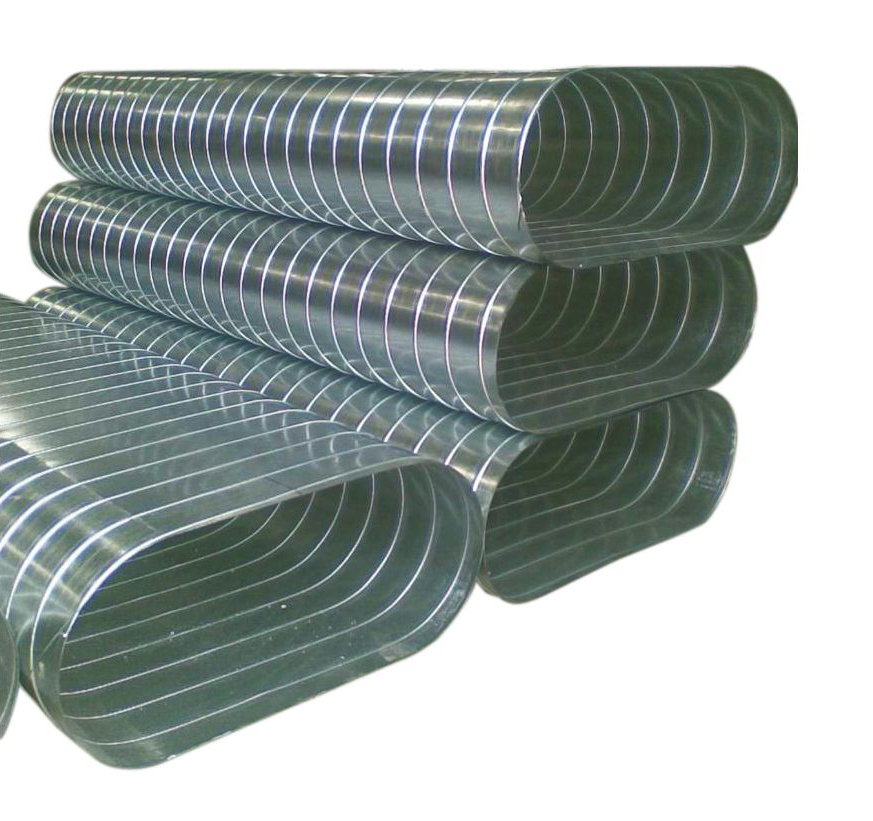

Specification

Thickness:

0.60 [24 G] to 1.00 mm [20 G]

Thickness of flat-oval spiral ducts as per SMACNA “HVAC Duct Construction Standards“ – 1985

| Major Axis Duct Width “B” | Spiral Duct Thickness Gauge [mm] | Duct Fittings Thickness Gauge [mm] |

|---|---|---|

| To 24” | 24 [0.63] | 20 [1.00] |

| 25” to 36” | 22 [0.80] | 20 [1.00] |

| 37” to 48” | 22 [0.80] | 18 [1.25] |

| 49” to 60” | 20 [1.00] | 18 [1.25] |

| 61” to 70” | 20 [1.00] | 16 [1.60] |

FLAT OVAL SPIRAL DUCT AND FITTINGS

Flat Oval Duct has been designed for restricted space conditions that cannot accept round spiral duct. Flat Oval pipe is fabricated in spiral lock seam or longitudinal welded constructions.

Advantages of using Flat Oval Duct:

Fully machine fabricated and hence appealing well.

Light weight due to spiral reinforced wall

Low frictional loss and hence no turbulence

Long run in continuous length up to 3 meters

Simple joining techniques

Reduced space requirements in depth or height

ACOUSTICALLY INSULATED SPLITTERS

Flat Oval and Spiral acoustic splitters for Sound Attenuators is made as Flat Oval Duct but with perforated option with the splitter infill with fiberglass wool / Rockwool which eliminates the use of GI Frame work and reduces the labour for fabrication and fixing of splitters in to the Attenuator Box. The Aero dynamic construction on both the ends facilitates the air movement smoothly without any friction loss/pressure loss. The fully perforated oval shape increases free sound Attenuator and reduces the length normally required with conventional splitters.

Suitable for use in line duct meant for air conditioning and ventilation system

DG Air intake system. Also suitable for sound Attenuators

Air Inlet/Outlet air duct Attenuators

Fan/Blower Silencer ducts etc

Pre - Insulated Double-walled Flat-oval Spiral Duct Systems

Thermal/Acoustic Insulation: A double -walled insulated Flat-oval Spiral Duct consists of an external pressure tight metal shell, a 12.5/25/50mm thick of fiberglass/mineral wool/puf insulation and internal plain protective metal liner for thermal insulation or perforated metal inner liner for acoustic insulation.

| Oval Duct Size Height (A) | ||||||||

|---|---|---|---|---|---|---|---|---|

| WIDTH | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 |

| 425 cp | 600 | 590 | 555 | 0 | 0 | 0 | 0 | |

| 450 cp | 660 | 625 | 595 | 565 | 0 | 0 | 0 | |

| 480 cp | 690 | 675 | 640 | 615 | 0 | 555 | 0 | |

| 500 cp | 740 | 700 | 675 | 645 | 615 | 585 | 555 | |

| 560 cp | 810 | 800 | 765 | 740 | 710 | 680 | 600 | |

| 600 cp | 890 | 865 | 830 | 800 | 770 | 745 | 715 | |

| 630 cp | 930 | 910 | 875 | 850 | 820 | 790 | 760 | |

| 650 cp | 960 | 935 | 910 | 880 | 850 | 820 | 795 | |

| 710 cp | 1050 | 1030 | 1000 | 975 | 950 | 915 | 890 | |

| 750 cp | 1115 | 1100 | 1065 | 1035 | 1010 | 975 | 950 | |

| 800 cp | 1200 | 1175 | 1145 | 1115 | 1085 | 1055 | 1030 | |

| 850 cp | 1275 | 1250 | 1225 | 1195 | 1165 | 1135 | 1110 | |

| 900 cp | 1350 | 1330 | 1300 | 1270 | 1250 | 1215 | 1185 | |

Shree Venus flexible ducts are manufactured from the State-of-the-Art Australian Technology, are extremely versatile and flexible ducts arc suitable for all high and low velocity air conditioning and ventilation systems.

Shree Venus flexible ducts are manufactured by laminating high quality Aluminium foil, two ply polyester film over a high quality spring steel wire helix to give excellent strength and flexibility.

Shree Venus ducts are strong, durable and fire resistant with flexibility of being compressed to 10% of its extended length.

Specification for insulated / uninsulated

Size Range: 100mm to 500mm

Compression: 10%

Standard Length: 10 metres

Temperature Range: -30°C to 110°C

Steel Wire Thickness 1. 00mm to 1. 2mm

Pressure Rating: 250mm WG(+ve) 25mmWG(-ve)

Insulation material: Fiberglass wool 25mm thick having density of 16kg./M3 or 24Kg./M3

Shree Venus Energy System Pvt.Ltd. are involved in the manufacturing of all types of ducting for HVAC Industry. Shree Venus also manufactures Semi Flexible Aluminium Ducts suitable for high velocity air conditioning and heating and ventilation industries.

Advantages of Shree Venus make Aluminium Semi Flexible Ducts:

Shree Venus semi flexible ducts are manufactured from a corrugated strip specially wound to produce a tube with a double overlapped and crimped joint to ensure pressure tightness to 20” WG. Shree Venus Flexible Ducts uses double overlapped joint and extra deep corrugation to increase the flexibility.

Shree Venus semi flexible ducts are relatively self supporting without sagging while maintaining great cross section strength.

Suitable for use in Chimney Hood.

Ideal for use in short forming connection of HVAC Ducting.

Suitable for open ducting without false ceiling.

Suitable for use in fumes Extract/Toilet ventilation, Kitchen Exhaust Ducting / Hoods.

Acoustically treated flexible ducts suitable for use in in-line duct as silencers.

Suitable for use in reducing the fan sound as silencer.

Complies with BS 476 part 6, 7 and 8 for Fire Resistance.

Materials Offered

Copper

Aluminium

Stainless Steel

Brass and

Galvanised Iron and Steel etc

Sizes Available

50mm to 500mm

Suitable for velocity up to 3000 FPM

Working Pressure : 20” WC Positive / Negative

Metal Core : Aluminium – 0.1mm thickness.