- Call Us : 044 - 4301 6191

- Email us : marketing@shreevenus.com

Pre-Assembled Flexible Duct Connector eliminates the duct system noises and vibrations All air duct installations for heating, cooling or ventilation are attached to mechanical equipment containing a fan or blower, Vibrations, noises and rattles resulting from operation of the fan or blower are transmitted into the metal ducts which carry the noises throughout the system.

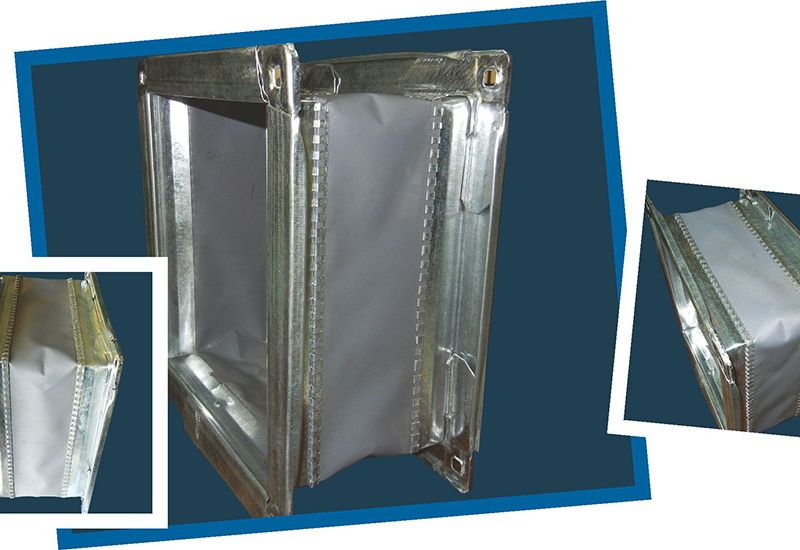

In order to isolate the vibration and noises to the source, an air-tight flexible joint, consisting of a fabric which is secured to sheet metal on both sides, must be inserted between the equipment and the ductwork. This flexible joint is called a “Flexible Duct Connector”.

ROLLFORMING LOCK

The double–lock gripping fingers of metal-to fabrics add tremendously holding power, compared with conventional single fold method.

INDUSTRIAL / COMMERCIAL APPLICATIONS:

The Material can be offered with TDF on both sides of flexile connector. The product is designed to be compatible with both TDC/TDF Roll Formed Flanges.

This products can also be supplied with insulated flexible connector with 2 layers of Fabrics sandwiched with fiberglass wool.

FABRICATING A FLEXIBLE CONNECTION:

HOW TO STIFFEN FLEXIBLE CONNECTOR

When installing large size flexible connectors in a duct system, some type of stiffening agent is usually required to keep the unit relatively rigid. Some contractors use angle iron, while in many cases a bar slip connection is used to achieve this result. Now it is possible to save valuable time and material by forming Venus Roll Loc seam formed on Metal Fab, to rigidize the connector over long sections. Here is how it is done.

This simple method of stiffening the sides of Roll Loc Flexible Connector can eliminate the costly addition of angle iron used to perform this job.